Perfect Railway Wheel Production Process and Other Amazing Manufacturing Methods. Don’t Miss!

Railway wheels play a crucial role in the smooth and efficient operation of trains. The production process behind these essential components is a fascinating blend of precision engineering and cutting-edge technology. In this article, we will delve into the intricate details of the perfect railway wheel production process, as well as explore other amazing manufacturing methods that are revolutionizing various industries.

The production of a flawless railway wheel begins with the careful selection of high-quality raw materials. Only the finest grades of steel are chosen, ensuring the durability and strength required to withstand the immense forces encountered on the tracks. Once the raw materials are obtained, they undergo a series of meticulously controlled processes to shape them into the desired form.

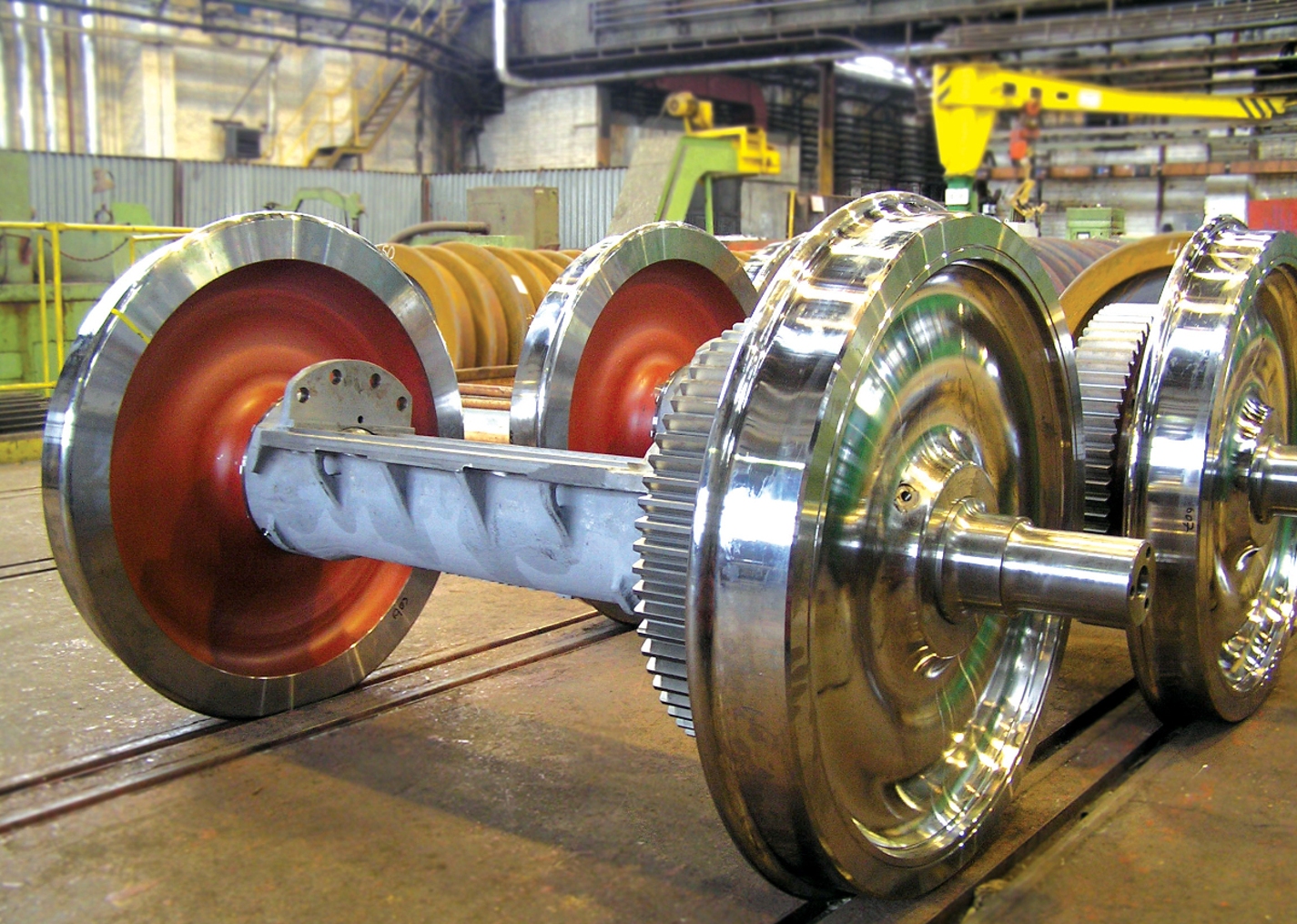

One of the key steps in the production process is the precision forging of the railway wheel. This involves subjecting the heated steel billet to enormous pressure, causing it to take on the shape of a wheel. The forging process not only imparts the necessary shape but also enhances the mechanical properties of the wheel, making it more resistant to wear and fatigue.

After forging, the railway wheel undergoes a series of machining operations to refine its shape and dimensions. Computer-controlled lathes and milling machines are employed to achieve the desired level of accuracy. The surface of the wheel is carefully smoothened, eliminating any imperfections that may affect its performance. This meticulous machining process ensures that each railway wheel meets the stringent quality standards set by the industry.

To enhance the durability and longevity of the railway wheel, a heat treatment process is employed. The wheel is subjected to controlled heating and cooling cycles, which significantly improve its mechanical properties. This heat treatment not only strengthens the wheel but also enhances its resistance to corrosion and wear.

Once the production process is complete, each railway wheel undergoes rigorous quality control inspections. Advanced non-destructive testing techniques, such as ultrasonic and magnetic particle testing, are employed to detect any internal flaws or defects. Only the wheels that pass these stringent tests are deemed fit for use in the railway industry.

Apart from the perfect railway wheel production process, the world of manufacturing is teeming with other amazing methods that are pushing the boundaries of what is possible. From additive manufacturing, also known as 3D printing, to robotic assembly lines, these cutting-edge techniques are revolutionizing various industries.

Additive manufacturing allows for the creation of intricate and complex structures with unprecedented precision. By building up layers of material, additive manufacturing eliminates many of the constraints associated with traditional manufacturing methods. This technology has found applications in aerospace, automotive, and medical industries, enabling the production of lightweight components and customized medical implants.

Robotic assembly lines are another remarkable advancement in manufacturing. With the help of advanced robotics and artificial intelligence, these assembly lines can carry out intricate tasks with unmatched speed and precision. By automating repetitive and labor-intensive processes, manufacturers can achieve higher productivity, improved quality control, and reduced costs.

In conclusion, the perfect railway wheel production process showcases the remarkable fusion of precision engineering and advanced technology. From the careful selection of high-quality raw materials to the application of heat treatment and stringent quality control inspections, every step is meticulously executed to ensure the production of flawless wheels. Furthermore, the manufacturing world continues to astonish with its innovative methods, such as additive manufacturing and robotic assembly lines. These advancements are revolutionizing various industries, pushing the boundaries of what can be achieved. Don’t miss the opportunity to explore the captivating world of manufacturing and its incredible feats!

Video: